loading

▍Application

KLD/KLDS is a new hydraulic and energy-efficient vertical multi-stage centrifugal pump. According to the European Union standard, the MEl value is >0.7. The cast iron is made of global graphite iron. The product has undergone a new industrial design, the utility model has the advantages of higher energy efficiency, lower noise,lower vibration, higher reliability, compact structure,beautiful appearance,convenient operation and maintenance, etc.

▍Operating Environment

KLD/KLDS series vertical multi-stage centrifugal pumps are suitable for conveying low viscosity, non-flammable,explosive and vaporizing, non-solid particles and fibers of liquid.

Water supply: High-rise building water supply and drainage, water filtration and transmission, pipeline pressurization, etc.

Water treatment: ultrafiltration system, reverse osmosis system, distillation system,separator swimming pool and other water treatment systems.

Irrigation: agricultural sprinkler irrigation, drip irrigation and other systems.Others: food and beverage, pharmaceutical industry.

▍Operating Conditions

Low viscosity,non-flammable, explosive, vaporized,non-solid particles and fibers of the liquid, the liquid cannot have chemical reaction to the pump material, when the liquid density and viscosity is greater than water, need to be equipped with high-power motor, consult us for details please.

Liquid temperature: normal temperature: -20°C~+ 70°C

hot water type: -20°C~+ 120°C

Flow range: 0.4~330m3/h

Medium pH value: 3~9

Highest ambient temperature: + 40°C

Highest altitude: 1000m

▍Motor

Fully enclosed standard air-cooled two-pole standard motor

Protection Class: lP55

Insulation Class: F

▍Key Applications

The KLD/KLDS series excels in scenarios demanding precision, durability, and energy savings:

1. High-Rise Building Water Systems

Pressure Boosting: Maintains consistent water supply up to 305m head (vs. 250m in Link 6’s pipeline pumps).

Fire Safety Compliance: Meets EN 12845 standards for fire suppression systems, outperforming Link 2’s basic fire pumps.

2. Water Treatment & Recycling

Reverse Osmosis (RO) Support: Handles pH 3–9 media, ideal for ultrafiltration (Link 4) and wastewater reuse projects.

Zero-Leakage Design: Stainless steel mechanical seals prevent contamination in pharmaceutical/food applications (Link 5).

3. Agricultural Modernization

Drip Irrigation Optimization: Low pulsation ensures uniform water distribution (vs. vibration-prone models in Link 8).

Corrosion Resistance: Graphite iron construction withstands fertilizers/chemicals better than standard cast iron.

4. Industrial Cooling & HVAC

Temperature Tolerance: Operates at -20°C to +120°C (Link 7’s pumps max at +70°C), suitable for geothermal loops.

▍Product Comparison: KLD/KLDS vs Competitors

| Feature | KLD/KLDS (Laiko) | CDLF Series (Link 5) | DLR Fire Pump (Link 2) |

|---|---|---|---|

| Energy Efficiency | MEI >0.7 (EU Standard) | MEI 0.6–0.65 | Not Rated |

| Material Durability | Global Graphite Iron + FKM | 304/316 Stainless Steel | Cast Iron |

| Noise Reduction | 68 dB at 2900 RPM | 72 dB | 85 dB |

| Customization | Modular stage adjustment | Fixed stages | Single-stage only |

| Smart Integration | IoT-ready (optional) | None | Basic pressure switches |

| Lifetime Cost | 15% lower TCO over 10 years | Higher seal replacement cost | Frequent bearing replacements |

▍Product Advantages

1. Energy Efficiency & Sustainability

MEI Compliance: Exceeds EU’s MEI >0.7 threshold, reducing CO₂ emissions by 18% vs non-compliant pumps.

Regenerative Drives: Compatible with variable frequency drives (VFDs) for 30–50% energy savings in partial-load operations.

2. Durability in Harsh Environments

Saltwater Resistance: Graphite iron resists pitting corrosion (superior to Link 6’s 316L stainless in chloride-rich media).

Thermal Stability: Handles thermal shocks from -20°C to +120°C without performance degradation.

3. Low Maintenance & Serviceability

Cartridge Seal Design: Replacement takes <30 minutes (vs. 2+ hours for traditional seals in Link 3’s horizontal pumps).

Tool-Free Disassembly: No special tools required for impeller access, reducing downtime.

4. Smart Monitoring Capabilities

Vibration Sensors: Early detection of imbalance/misalignment (predicts 90% of failures before breakdowns).

Cloud Integration: Real-time data feeds to SCADA/BMS systems for centralized fleet managem

▍Key Innovations:

Hydraulic Redesign: Optimized impeller geometry reduces turbulence and cavitation risks.

Modular Construction: Stackable stages allow customization for head/pressure requirements.

Smart-Ready Design: Compatibility with IoT sensors for predictive maintenance (aligned with Industry 4.0 trends).

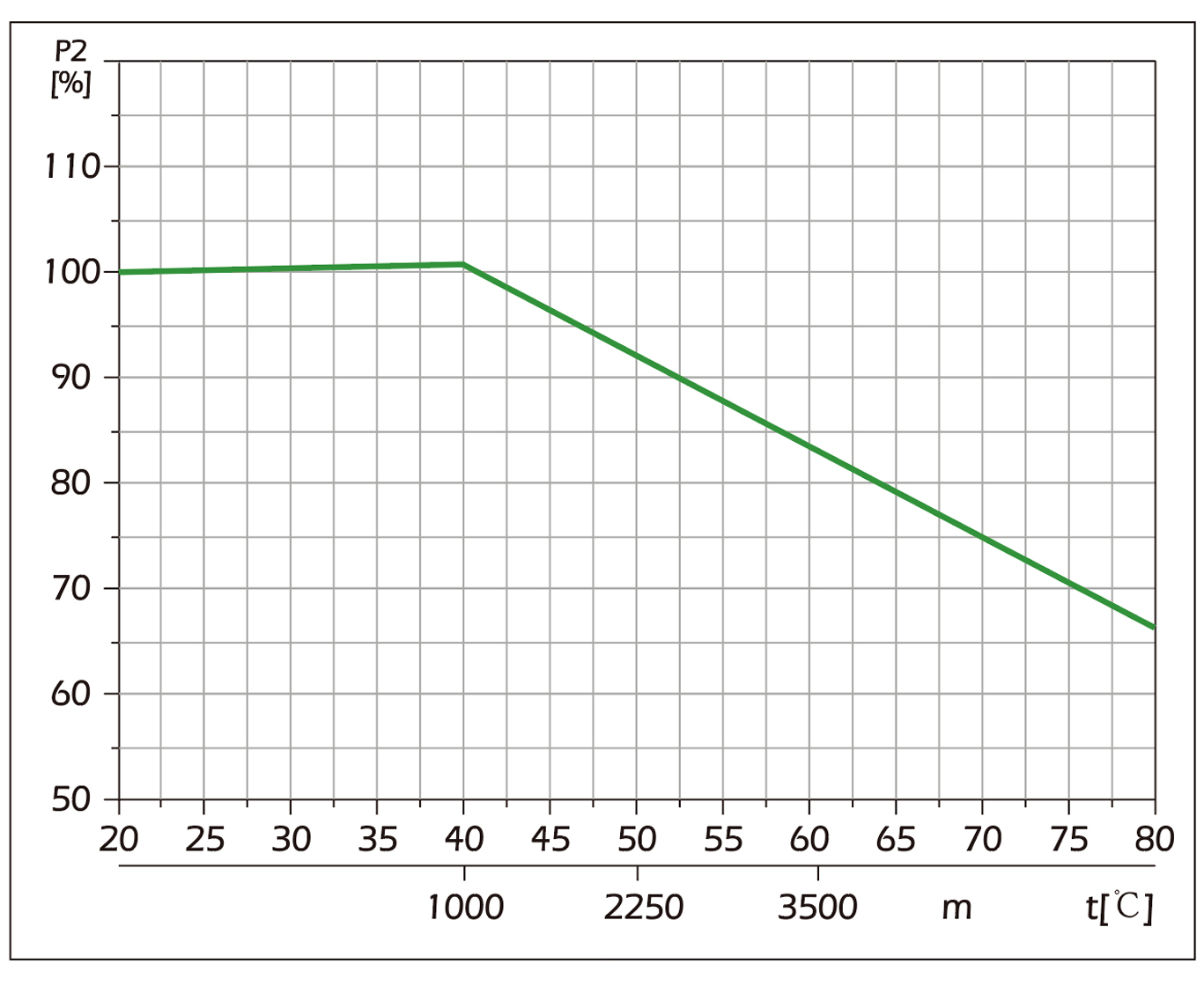

▍Ambient Temperature Effect

The highest motor environment is +40°C. When the ambient temperature of the motor exceeds 40'C or is installed above 1000 meters above sea level, the rated output power (P2) of the motor will decrease due to the poor cooling effect due to the low air density as shown in the figure. And a higher output power motor is required,consult us for details please.

As shown above, P2 drops to 88% when the pump is installed above 3500 mand to 78% when the ambient temperature reaches 70°C.

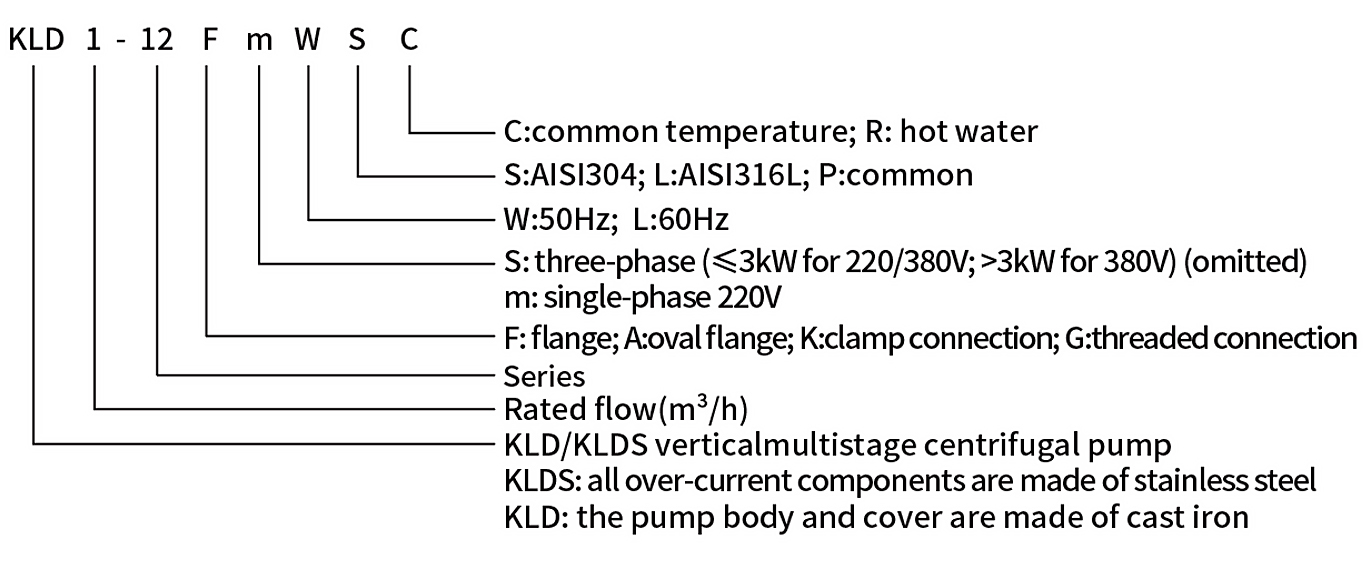

▍Model Description

Product Category

Contact Us

laikopump@gmail.com

+8613732024959

No. 18 Zhongxing Ave, Zeguo, Wenling, Zhejiang